In mathematics, a manifold is a topological space that locally resembles Euclidean space near each point.

Resources

A valve is a device that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways.

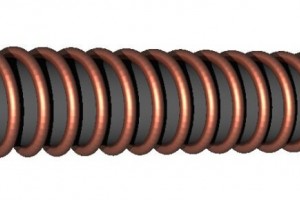

A solenoid is a coil wound into a tightly packed helix. The term was invented by French physicist André-Marie Ampère to designate a helical coil.

A power inverter, or inverter, is an electronic device or circuitry that changes direct current (DC) to alternating current (AC).

A counter circuit is usually constructed of a number of flip-flops connected in cascade. Counters are a very widely used component in digital circuits, and are manufactured as separate integrated circuits and also incorporated as parts of larger integrated circuits.

A pressure regulator is a control valve that reduces the input pressure of a fluid to a desired value at its output. Regulators are used for gases and liquids, and can be an integral device with an output pressure setting, a restrictor and a sensor all in the one body, or consist of a separate pressure sensor, controller and flow valve.

A catalytic converter is an exhaust emission control device that converts toxic gases and pollutants in exhaust gas from an internal combustion engine into less-toxic pollutants by catalyzing a redox reaction (an oxidation and a reduction reaction).