A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment.

Resources

A mechanical seal is a device that helps join systems or mechanisms together by preventing leakage (e.g. in a pumping system), containing pressure, or excluding contamination. The effectiveness of a seal is dependent on adhesion in the case of sealants and compression in the case of gaskets.

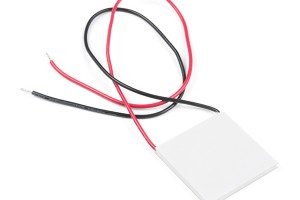

Thermoelectric cooling uses the Peltier effect to create a heat flux at the junction of two different types of materials. A Peltier cooler, heater, or thermoelectric heat pump is a solid-state active heat pump which transfers heat from one side of the device to the other, with consumption of electrical energy, depending on the direction of the current.

A contactor is an electrically-controlled switch used for switching an electrical power circuit. A contactor is typically controlled by a circuit which has a much lower power level than the switched circuit, such as a 24-volt coil electromagnet controlling a 230-volt motor switch.

A relay is an electrically operated switch. It consists of a set of input terminals for a single or multiple control signals, and a set of operating contact terminals. The switch may have any number of contacts in multiple contact forms, such as make contacts, break contacts, or combinations thereof.

In electronics, a ferrite core is a type of magnetic core made of ferrite on which the windings of electric transformers and other wound components such as inductors are formed. It is used for its properties of high magnetic permeability coupled with low electrical conductivity (which helps prevent eddy currents).

Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations.

Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.